Comparison of Sodium Concentration between Ham Dry Cured with NaCl and a KCl/NaCl Mixture

ABSTRACT

Cured products are popular in developed countries; however, due to an increased risk of cardiovascular disease, associated in part with higher sodium consumption in the human diet, it is convenient to explore alternative food preservation methods without altering the chemical properties of ham. Legs of pigs (corresponding to the pelvic member) from the same batch raised in an extensive production system were processed using the traditional method of cured ham. The left legs were cured using a treatment with NaCl (treatment A), while a mixture of NaCl / KCl (treatment B) was used for the right legs. Changes in weight, Na and K concentration, as well as pH were evaluated and compared at the end of the process. The inclusion of KCl produces a decrease in Na (p < 0.05) and an increase in K (p < 0.05). It was recorded 11.11 ± 1.467% Na and 1.59 ± 0.161% K in treatment A and 8.74 ± 1.156% and 3.89 ± 0.542% K in treatment B. Regarding pH, the values for treatment A were 5.36 ± 0.064 and 5.48 ± 0.101 for treatment B (p > 0.05). This indicates that it would be possible to replace sodium chloride (NaCl) with potassium chloride (KCl) at 25% in the preparation of artisanal ham enables the production of healthier foods for many occasions. This also allows us to replace sodium with other salts without altering the distinctive properties of the final product.

KEYWORDS

Curing; Food preservation; Pork; Maturation; Salt concentration; Substitution NaCl

INTRODUCTION

Cured ham is a high-value product that is strongly associated with Mediterranean European countries, where it represents an important source of income. In fact, Spain produces more than 40 million hams annually. The ham healing process requires a long time, resulting in a high production cost in comparison with the wholesale of pig carcasses; however, the curing process length is necessary in order to achieve the desired characteristics of a good quality ham [4,8,10,16,24,29]. Noncommunicable Diseases (NCD), such as cardiovascular diseases, have been associated with diets rich in sodium (Na). At present, according to the orientation of the World Health Organization (WHO) on the consumption of Na for adults [11,28,34], it is strongly recommended to consume a maximum of 2g of sodium per day, equivalent to 5g of sodium chloride (table salt) / day. Nonetheless, the daily intake of Na in many industrialized countries (typically consumed as NaCl) exceeds these recommendations [2,34], with cured meats that are in some cases more than 20% of the total amount of Na in the diet [15,20].

In order to reduce NaCl content in foodstuffs, other salts such as potassium chloride (KCl), calcium chloride (CaCl2) and magnesium chloride (MgCl2) have been used as alternatives [2,4,5]. In the results of a study of dressing, Aliño et al. [3] observed significant changes in the pattern of salting depending on the type of salts, the presence of KCl decreased water loss, while CaCl2 and MgCl2 had the opposite effect. However, the replacement of up to 50% of NaCl with KCl did not have a significant effect in the kinetics of salting with respect to the control group.

Sodium chloride is widely used in food production, due not only to the desirable organoleptic changes associated with the addition of NaCl, but also to its antimicrobial activity, since it acts as a food preservative [28]. The organoleptic changes are related to the role played by the NaCl in enzymatic reactions as the proteolysis, lipolysis, and oxidation, while the preservation is linked to the reduction of the water activity (aw) in the food product [8]. These results demonstrate a positive perspective, for the partial replacement of Na. Despite the beneficial effects of NaCl, there have been a number of measures to reduce Na in human diets. The high consumption of Na has been associated with conditions such as cardiovascular disease and hypertension, also exposing individuals to an increased risk of stroke [28,30].

The pH provides information on the qualitative properties of the flesh, being quick and relatively easy to implement. In addition, it has a direct or indirect influence on the color, tenderness, flavor, water holding capacity and the shelf life of the meat so that, to a certain extent, it also influences the sensory characteristics and the fitness for the processing of meat [6,17,20]. The objective of this study was to evaluate the feasibility of producing high value ham, working with small pig producers and using lower Na concentrations, in order to produce a healthier product and to diversify the sources of income for farmers.

MATERIAL AND METHODS

Sample Size and Unit Analysis

This is a prospective technical feasibility study. Sample size was determined considering Na concentration, since it is the most important public health parameter in this study. A minimum of 5 legs per group are necessary to detect a difference of 10 and 8% Na in ham, with 80% power and 95% confidence, for a one-tailed statistical test [14,27,31]. The pigs were raised in the Linares province (latitude-36.1431084 and longitude-71.8260498), Chile. These animals were hybrids (Duroc with commercial line); they were raised under a mixed system based on pastures and finished with grains. The animals were maintained, until they reached a final live weight of 110kg. They were then sent to a slaughterhouse, and the carcasses were inspected in accordance with Chilean law. For the test, one leg of each animal used for treatment A (left) and B (right) was taken.

Cured Ham Elaboration Process

Ten legs of the five slaughtered pigs were subjected to a dry curing process based on the method of the Spanish Ministry of Agriculture Fisheries and Food [25] for the development of serrano ham using two different curing treatments. The left legs (average weight 10.28 ± 0.46kg) were treated with NaCl 100% (Treatment), while the right legs (average weight 10.28 ± 0.69kg) were treated with a NaCl / KCl (75% and 25%) mixture.

Briefly, the production of cured ham was carried out in four stages (salting, post-salting, drying and ripening). First, during the salting, the ham was covered with salt for 1.5 days kg-1 of weight and stored at 3 °C [9]. Secondly, during the post-salting, the salt retreated, and the ham was washed and dried. While drying, following a sequence of gradual and progressive increase in temperature and exposure time, the ham was stored at 3 °C for 95 days. For a uniform preparation, a drying and ripening platform was used, which aimed to contain the hams hanging and protected from the insects, so that they could reach the required ambient temperature of 20 to 30 °C [18]. Finally, during the maturation stages, the ham was stored on shelves at room temperature for 280 days.

pH Evaluation

pH Evaluation We performed pH (Hanna Instruments® model 4467, HI 9025, Canton, Massachusetts, EE.UU.) measurements at the end of the curing process for all samples. All analyses were performed in duplicate.

Na and K Measurements

The final Na and K concentrations were assessed by atomic absorption spectroscopy (AAS) (Tja Solutions® AA spectrometer, Model Solaar 969mk II, Cambridge, Inglaterra), according to the method AOAC 985.35. PRT-711.02.012 [21].

Statistical Analysis

To analyze normality condition of the data we used Shapiro- Wilks normality test. For descriptive statistic we used means and S.D. for the pH, Na and K concentration. Data does not have normal distribution, then to analyze the difference between medians of pH, Na and K concentration for treatments A and B, we used Kruskall- Wallis test with a 95% confidence level. In addition, the Pearson correlation coefficients were tested between pH, Na, and K with a 90% confidence level.

RESULTS AND DISCUSSION

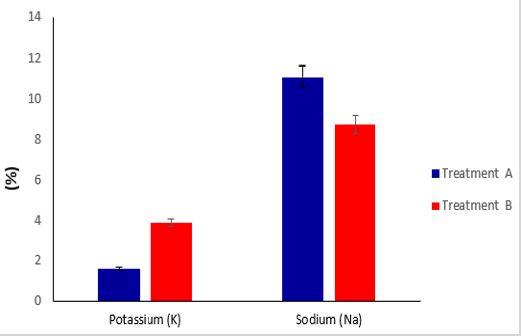

There was a lower Na content in treatment B (8.74 ± 1.156 % of Na) (p < 0,05), and a higher amount in K for the same group in relation to the treatment (11.11 ± 1.467 % of Na) (p < 0,05) that was salted with 100% sodium chloride (Figure 1). According to Armenteros [8] and Toldra [32], treatment B is within the expected range for raw ham with its Na values. With regard to pork values, the Na/K relationship is inverse to that found in treatments A and B, as Na is lower (0.50 ± 0.068) (p < 0,05) and K is greater (0.98 ± 0.146) (p < 0.05).

The greatest amount of Na in artisanal hams (treatment A and B), with respect to the recommended values, is due to the high time of salt used in this work in the development of raw hams (1.5 days per kg body weight) [7,8,33]. As expected, the hams salted with a mixture of NaCl and KCl (treatment B) showed an increase in the content of the ion K+, which increased substantially with regard to the concentration of KCl added to the mixture of salts.

Several strategies have been proposed to reduce NaCl without much alteration in the curing process. Studies have shown that the partial replacement of NaCl by other chloride salts, for example KCl, CaCl2 and MgCl2, could be one of the best alternatives to reduce the sodium content in meat products. The correlation between Na and K was only important (r = 0.8; p=0.10) in treatment B, showing K was retained in the ham as well as Na. The increase of K content in the food is healthy according the WHO recommendation [3,8,13,24].

As has been previously described in the literature, in order to avoid an excessive dehydration of the flesh, during half of the drying and maturation process, a thin layer of butter was applied onto the product and was maintained until the end of the production process [2,4,5]. Dehydration during the four steps of the process was 8.5% to 21.5% for salting and 33.3% for post-salting, drying, and maturation. All production stages showed patterns of dehydration that were clearly distinguishable from one other. These patterns could be used as an alternative method to determine the start and end of each of the four steps in the production process of cured ham for artisanal producers, who may not have the technology available to completely control the environmental conditions and humidity due to economic constraints.

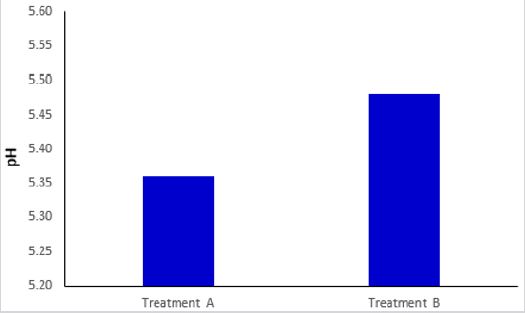

The final pH value of the ham for treatment A and B was 5.36 ± 0.064 and 5.48 ± 0.101, respectively, and this difference was not significant (p > 0.05) (Figure 2). These values are appropriate for the ham’s chemical characteristics [19,23]. The rate and extent of decrease in the pH after the slaughter of the animals is determined by the formation of lactic acid in the muscle. This is conditioned by the nature and condition of the muscle at the time that the flow of blood stops, although the changes taking place in the muscle after slaughter have their origin during the processes of desensitization. This decrease in pH has an influence on the organoleptic properties and hygienic meat, as well as on their aptitude for technological transformation, and are conditioned by genetic factors and by the stress produced in the animals before and during slaughter [1,8,22]

Therefore, meat product manufacturers are in a constant search for alternatives to salting techniques that are faster and more efficient, allowing a homogeneous distribution of salt in the meat, reducing the processing time and improving the final quality [12,26].

CONCLUSION

The inclusion of KCl in artisanal curated ham produces a decrease in Na and an increase in K. The replacement of NaCl with KCl in the ham curated process was not alter the final product and the pH with the inclusion of KCl. Thus, this modification has potential use in the food industry. For posterior work, we propose reducing the salted time using KCl to increase the reduction of the Na final content.

REFERENCES

- Albarracín HW (2009) Simultaneous salting and thawing in brine to obtain cured ham from Iberian pigs. Tesis doctotal, Departamento de Tecnología de Alimentos, Universidad de Valencia, Valencia, Spain.

- Aliño M, Grau R, Fuentes A, Barat J (2010ª) Influence of low-sodium mixtures of salts on the post-salting stage of dry-cured ham process. J Nutr Health Food Eng 99(2): 198-205.

- Aliño M, Grau R, Fuentes A, Barat J (2010c) Characterization of pile salting with sodium replaced mixtures of salts in dry-cured loin manufacture. J Nutr Health Food Eng 97(3): 434-439.

- Aliño M, Grau R, Fuentes A, Barat J (2010b) Physicochemical changes in dry-cured hams salted with potassium, calcium, and magnesium chloride as a partial replacement for sodium chloride. Meat Sci 86(2): 331-336.

- Aliño M, Grau R, Toldrá F, Blesa E, Pagán M, et al. (2009) Influence of sodium replacement on physicochemical properties of dry-cured loin. Meat Sci 83(3): 423-430.

- Álvarez ÁD (2002) Influence of ante-mortem conditions and slaughter technology on the quality of pork. Tesis doctoral, Departamento de Tecnología de Alimentos, Universidad de Murcia, Nutrición y Bromatología, Murcia, Spain.

- Andrade MJ, Rodas E, Durbán A, Moya A, Córdoba J (2012) Characterization and control of microbial black spot spoilage in drycured Iberiam ham. Meat Sci 23(1): 128-136.

- Armenteros CM (2010) Reducción de sodio en lomo y jamón curados. Efecto sobre la proteólisis y las características sensoriales. Tesis doctoral, Departamento de Tecnología de los Alimentos, Universidad politécnica de Valencia, Valencia, Spain.

- Arnau J (1998) Tecnología de fabricación del jamón curado en distintos países. En Centro de Investigación y Tecnología Agroalimentarias (IRTA) y EUROCARNE, El jamón curado: Tecnología y análisis de consumo. 44th Simposio especial. International Congress of Meat Science and Technology, Barcelona, Spain, p. 9-24.

- Bajd F, Škrlep M, Čandek-Potokar M, Vidmar J, Serša I (2016) Use of multiparametric magnetic resonance microscopy for discrimination among different processing protocols and anatomical positions of Slovenian dry-cured hams. Food Chem 197: 1093-1101.

- Bibbins D, Chertow GM, Coxson PG, Moran AE, Lightwood JM, et al. (2010) Reductions in cardiovascular disease projected from modest reductions in dietary salt. N Engl J Med 362(7): 590-599.

- Caballero D, Caro A, Rodríguez PG, Durán ML, Ávila MM, et al. (2016) Modeling salt diffusion in Iberian ham by applying MRI and data mining. J Nutr Health Food Eng 189: 115-122.

- Choi YM, Jung KC, Jo HM, Nam KW, Choe JH, et al. (2014) Combined effects of potassium lactate and calcium ascorbate as sodium chloride substitutes on the physicochemical and sensory characteristics of lowsodium frankfurter sausage. Meat Sci 96: 21-25.

- de Blas I, Ruiz-Zarzuela I, Vallejo A (2006) WinEpi: Working in epidemiology. An online epidemiological tool. ISVEE 11: Proceedings of the 11th Symposium of the International Society for Veterinary Epidemiology and Economics, Cairns. Theme 4- Tools & training for epidemiologists: Poster session sesión, Australia./li>

- Desmond E (2006) Reducing salt: A challenge for the meat industry. Meat Sci 74(1): 188-196.

- Flores M, Ingram DA, Bett KL, Toldra F, Spanier AM (1997) Sensory characteristics of Spanish “serrano” dry-cured ham. J Sensory Stud 12(3): 169-179.

- García-García AB, Fernández-Valle ME, Castejón D, Escudero R, Cambero MI (2019) Use of MRI as a predictive tool for physicochemical and rheological features during cured ham manufacturing. Meat Sci 148: 171-180.

- García-Rey RM, García-Garrido JM, Quiles-Zafra R, Tapiador J, Luque de Castro MD (2004) Relationship between pH before salting and drycured ham quality. Meat Sci 67(4): 625-632.

- Grassi S, Casiraghi E, Benedetti S, Alamprese C (2017) Effect of lowprotein diets in heavy pigs on dry-cured ham quality characteristics. Meat Sci 131: 152-157.

- Greiff K, Mathiassen JR, Misimi E, Hersleth M, Aursand IG (2015) Gradual reduction in sodium content in cooked ham, with corresponding change in sensorial properties measured by sensory evaluation and a multimodal machine vision system. PLos One 10(9): 1-14.

- Instituto de Salud Publica (ISP) (2011) Procedimiento para determinaciónde sodio, potasio y calcio en alimentos. Método Espectrofotometría de Absorción Atómica de llama. Método AOAC 985.35. PRT-711.02.012. Instituto de Salud Publica (ISP), Santiago, Chile.

- Knecht D, Duziński K, Jankowska-Mąkosa A (2018) Pork ham and belly quality can be estimated from loin quality measurements? Meat Sci 145: 144-149.

- Laureati M, Buratti S, Giovanelli G, Corazzin M, lo Fiego DP (2014) Characterization and differentiation of Italian Parma, San Daniele and Toscano dry-cured hams: A multi-disciplinary approach. Meat Sci 96(1): 288-294.

- Lorenzo JM, Cittadini A, Bermúdez R, Munekata PE (2015) Influence of partial replacement of NaCL with KCL, CaCl2 and MgCl2 on proteolysis, lipolysis and sensory properties during the manufactrure of dry-cured lacón. Food Contr 55: 90-96.

- Ministerio de Agricultura Pesca y Alimentación (2019) Jamón Serrano: Definición y método de producción o elaboración. MAPA, Spain.

- Ojha KS, Keenan DK, Bright A, Kerry JP, Tiwari BK (2016) Ultrasound assisted diffusion of sodium salt replacer and effect on physicochemical properties of pork meat. Int J Food Sci Tech 51(1): 37-45.

- Ortega C, de Blas I, Simón MC, Gironés O, García J, et al. (2000) Programa informático aplicado al estudio temporal de procesos patológicos en poblaciones animales. Revue Scientifique et Technique de l’Office International des Epizooties 19(3): 735-743.

- Ravishankar S, Juneja VK (2014) Traditional preservatives: sodium chloride. In: Batt CA (Ed.), Encyclopedia of Food Microbiology 3: 1723- 1728.

- Schiavon S, Carraro L, Dalla M, Cesaro G, Carnier P, et al. (2015) Growth performance and carcass and raw ham quality of crossbred heavy pigs from four genetic groups fed low protein diets for dry-cured ham production. Animal Feed Science and Technology 208: 170-181.

- Segura J, Escudero R, Romero de Ávila MD, Cambero MI, López-Bote CJ (2015) Effect of fatty acid composition and positional distribution within the triglyceride on selected physical properties of dry-cured ham subcutaneous fat. Meat Sci 103: 90-95.

- Thrusfield M, Ortega C, de Blas I, Noordhuizen JP, Frankena K (2001) Win episcope 2.0: Improved epidemiological software for veterinary medicine. The Veterinary Record 148(18): 567-572.

- Toldrá F (2006) The role of muscle enzymes in dry-cured meat products with different drying conditions. Trends Food Sci Technol 17(4): 164- 168.

- Virgili R, Saccani G, Gabba L, Tanzi E, Soresi C (2007) Changes of free amino acids and biogenic amines during extended ageing of Italian drycured ham. Swiss Society of Food Science and Technology 40(5): 871- 878.

- World Health Organization (2012) Guideline: Sodium intake for adults and children. World Health Organisation (WHO), Geneva, Switzerland.

Article Type

Research Article

Publication history

Received date: September 11, 2020

Published date: September 18, 2020

Address for correspondence

Reinaldo Letelier, Department of Pathology and Preventive Medicine, Faculty of Veterinary Sciences, Universidad de Concepción, Chile

Copyright

©2020 Open Access Journal of Biomedical Science, All rights reserved. No part of this content may be reproduced or transmitted in any form or by any means as per the standard guidelines of fair use. Open Access Journal of Biomedical Science is licensed under a Creative Commons Attribution 4.0 International License

How to cite this article

Letelier R, González F, Melín P, Hernández P, Nova R, Gädicke P, Larenas- Muñoz F. Comparison of Sodium Concentration between Ham Dry Cured with NaCl and a KCl/ NaCl Mixture. 2020 - 2(5) OAJBS.ID.000217.